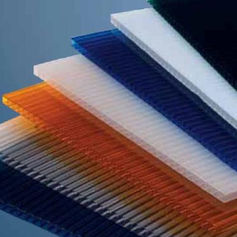

Corrugated Polycarbonate Sheet

Hollow polycarbonate is also often called structural polycarbonate, cellular polycarbonate, channeled polycarbonate or multilayer polycarbonate. The name “cellular” is used due to the structure of polycarbonate itself. The air remaining in the space (cell) between the separating walls inside the polycarbonate plate provides thermal insulation feature, and the filling material (separator) forming these walls provides both structural rigidity and flexibility to the polycarbonate plate.

Polycarbonate Hollow sheets provide a higher level of polishing performance where transparency together with high impact resistance is of utmost importance. These sheets have excellent properties, physical, mechanical, electrical as well as new, which explains their rising reputation in the building and decoration industry. These products are sold all over the world and make great contributions to the lives of consumers. The fact that it can be used in all areas makes it the ideal choice for coating in hospitals, sports fields and public infrastructure projects. It can be used on all transparent and textured surfaces.

Technical information

Polycarbonate is a unique engineering thermoplastic that combines high levels of mechanical, visual and thermal properties. The very usefulness of this material makes it suitable for use in many engineering applications. If corrugated polycarbonate is extruded in the form of a sheet, its visual and strength properties have made this material an ideal material to use in areas such as roofing and finishing.

1. Standard Sheet Dimensions and Weights

Corrugated polycarbonate sheet is produced in various colors and degrees of transparency to meet optimal roofing and finishing requirements.

2. Thermal Properties

a. service temperature

Rainbow multilayer polycarbonate can be used in varying temperatures. However, it is known that the mechanical performance of the material remains stable in long-term use and at temperatures from -40°C to +120°C.

b. thermal expansion

The linear expansion coefficient of polycarbonate material is 6.7x10-5 m/moC. This means that, at a delta of 50oC, the thermal expansion of the plate per linear meter is approximately 3 mm.

c. Thermal insulation and U-Value

Thermal insulation can be defined as resistance to heat resulting from the temperature difference between two substances. When we look at MWPC (Corrugated polycarbonate), we see that thermal insulation is important in materials used in areas where the external temperature and internal temperature are different from each other. Uses in closed structures such as sun lounges and indoor swimming pools can be given as a few examples of thermal insulation. U or R-Values are coefficients that determine the heat loss in glazing the walls of a building. If the U-Value decreases, thermal insulation increases.

3. Optical properties

a. Solar factor g-Value

The g-value shows how much of the sunlight hitting the plate is converted into heat. If the g-value increases, the solar yield potential through a plate increases.

The maximum sound transmission classes that can be achieved for a certain thickness according to DIN 52210-75 are stated below. Values are the results of standard weights.

5. Fire Performance

Polycarbonate corrugated sheet has good fire resistance properties and mainly has some fire performance

6. Protection against UV Rays

Radiation from the sun contains a harmful component, including UV rays, which cause the degradation of many polymeric materials, including polycarbonate. This is mostly related to factors such as geographical locations, seasons, etc. Polycarbonate sheets feature a specially co-extruded UV absorption and protection layer that provides long-term stability against harmful UV rays, provides protection against external weather conditions and preserves the original color and light transmission in accelerated weathering tests, as shown in the graphs below. The additive that provides this feature is generally applied with a co-extruder, and from time to time it can be mixed directly into the material.

Usage areas

Canopies in stadiums and bus stops

Lighting in corridors, passages and subway entrances

Bank ATMs

Tents for greenhouses and zoos.

Polycarbonate sheets used for building and decoration materials, greenhouse materials and insulation material blocks

Walls and roofs of greenhouses, department stores, performance centers and telephone booths, insulation shield of intercity roads and highways

Office buildings, hotels, villas, stadiums, schools, bus stops, terminals, hospitals, subway entrances and exit doors, etc.